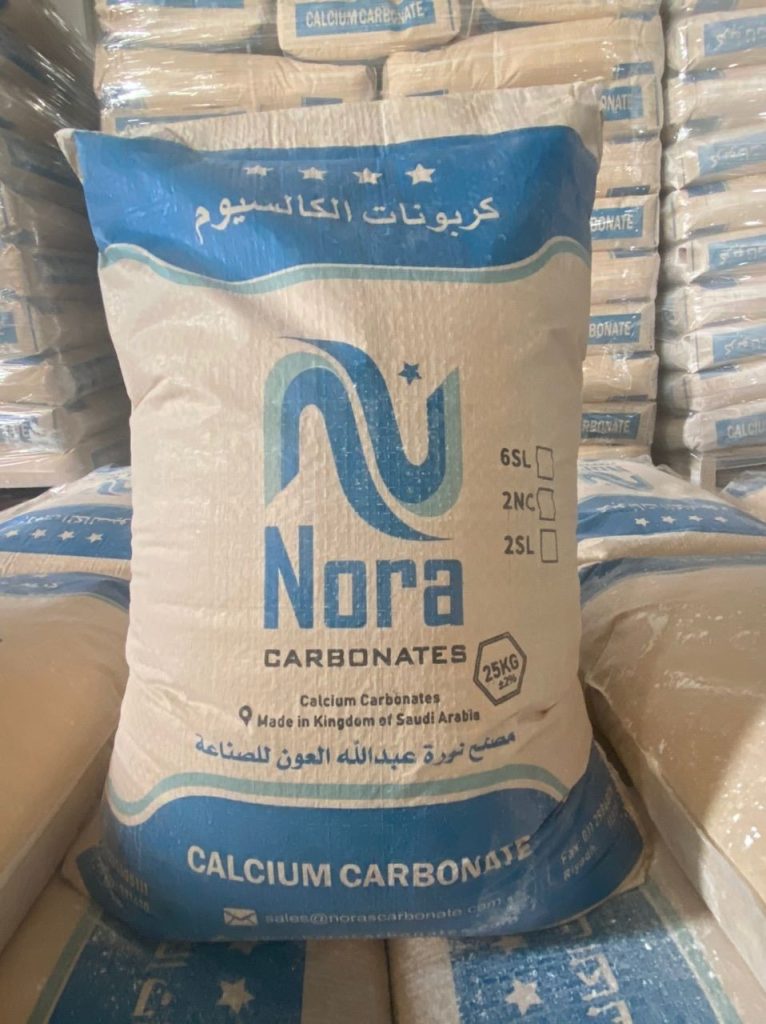

Calcium Carbonates

Product Description

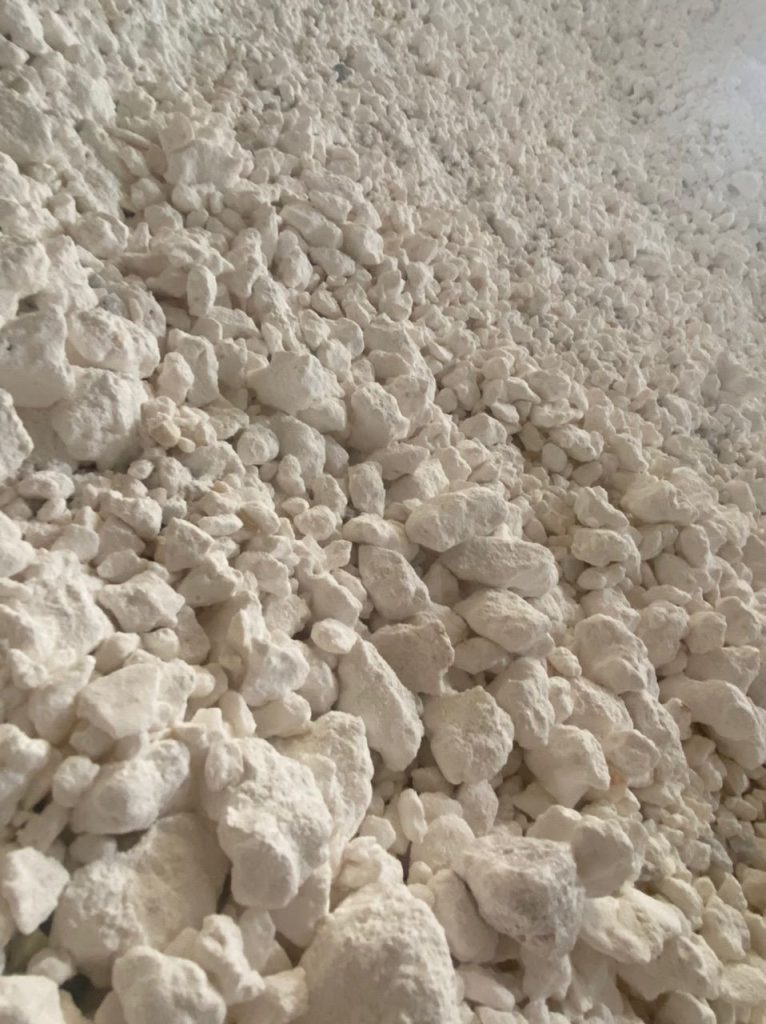

Industrial Raw Calcium Carbonate Media is made to meet the high standards of ANSI/AWWA B100-09 and ASTM E11 for test sieves. It is used as an industrial raw material along with other products like Silica Flour, Limestone, Aggregate, Quicklime, Talc, Volcanic Rock, and Abrasives.

Activated carbon helps remove contaminants and impurities through chemical adsorption. Activated charcoal filters are especially good at removing chlorine, sediment, volatile organic compounds (VOCs), and bad tastes and odors from water.

Calcite, a naturally occurring mineral, varies in properties. Its industrial use depends on factors like composition, particle size and shape, specific gravity, hardness, and color. In the glass industry, calcite powder must have a high and consistent CaO content and be free of impurities like Fe2O3. Rajasthan is known for its high whiteness calcite. Calcium Carbonate is also used in ceramics, including products like art ware, porcelain, pottery, floor tiles, and sanitary ware.

Calcium carbonate is widely used as a white filler and coating pigment in the paper, plastics, paints, and coatings industries. It is also used in the chemical industry, construction, environment, agriculture, and even for human consumption. The main use of calcium carbonate is in construction, either as a building material, limestone aggregate for roads, cement ingredient, or starting material for making builders’ lime by burning in a kiln. However, due to weathering from acid rain, pure limestone is no longer used for building; it is now used as a raw material for building materials.